Snow buildup on metal roofs can lead to serious safety hazards and property damage. That’s where our Snow Guards Rolling Machine comes in — a purpose-built, high-efficiency solution designed to produce metal snow retention profiles that prevent snow and ice from sliding off roofs. If you’re in the metal roofing or building accessory industry, this machine offers you a reliable, scalable way to manufacture snow rails that enhance roof safety and extend system durability.

What Is a Snow Guards Rolling Machine?

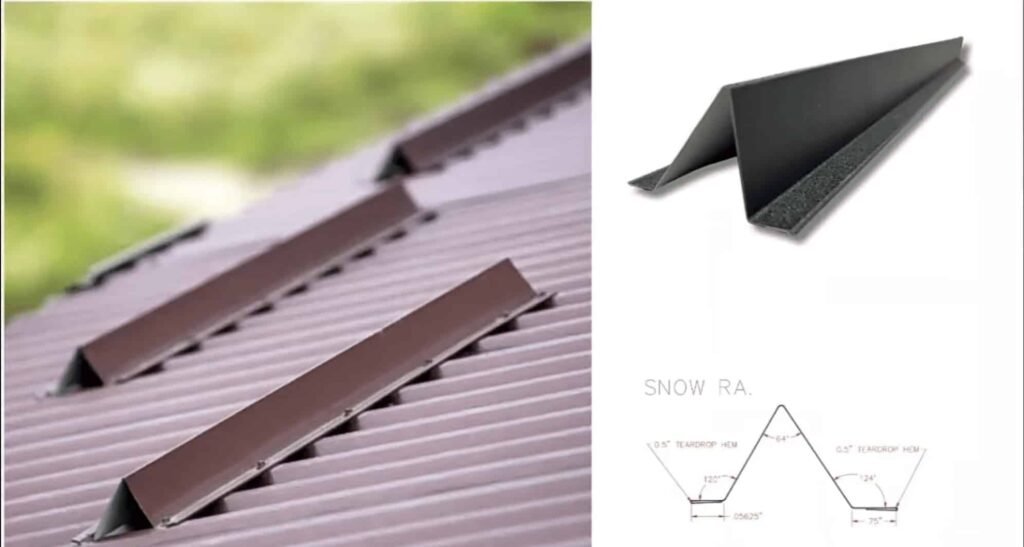

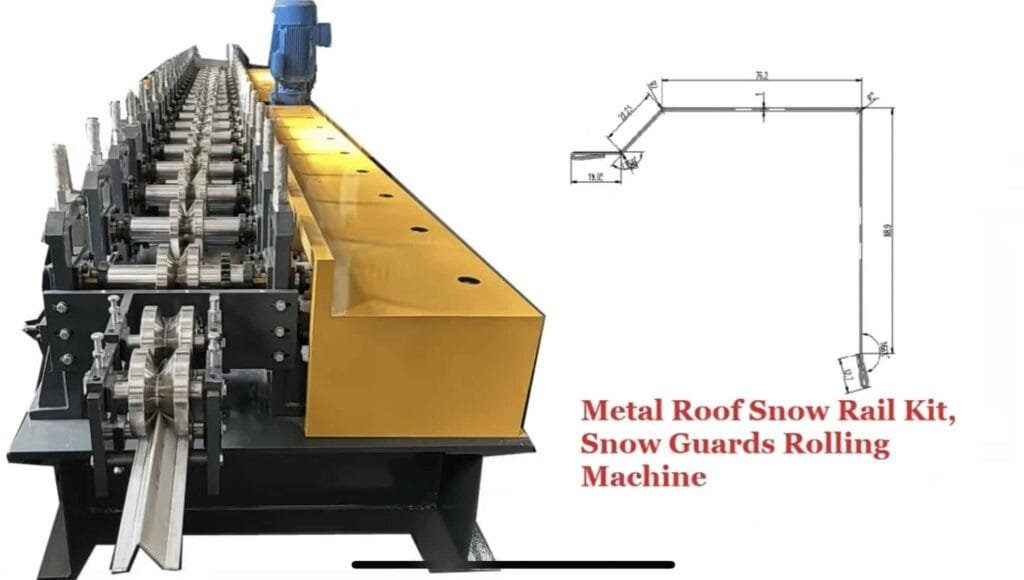

A Snow Guards Rolling Machine is a roll forming system engineered to create precise snow rail profiles from metal sheets or coils. These snow guards are installed on sloped metal roofs to hold accumulated snow and ice in place, preventing sudden sliding that can harm people, pets, vehicles, or property below.

Whether you’re producing snow stoppers for residential, commercial, or industrial roofing systems, this machine ensures consistent profile accuracy, high production speed, and excellent surface aesthetics.

Key Benefits of Using a Snow Guards Rolling Machine

✅ Improved Winter Roof Safety

Metal roofs are durable and attractive, but their smooth surfaces allow snow and ice to slide off easily during thawing periods. By producing and installing snow guards using our machine, you help building owners prevent dangerous snow slides that can lead to injuries or costly property damage.

✅ High-Speed, High-Quality Output

The system is optimized for fast and accurate roll forming. Depending on the profile type, you can achieve speeds of up to 15–25 meters per minute, making it ideal for medium to large-scale production needs.

✅ Flexible Raw Material Input

You can feed the machine with either metal coil or pre-cut sheet, depending on your production setup. The coil feeding option offers greater automation and continuous production, while sheet feeding allows for easier profile changeover and minimal material waste.

✅ Perfectly Formed Profiles

Thanks to precision-engineered forming rollers and a heavy-duty machine frame, your snow guards will come out with clean edges, uniform shapes, and consistent dimensions. These features ensure reliable roof attachment and a sleek, professional appearance.

Machine Features Overview

1. Coil/Sheet Feeding System

- Compatible with galvanized steel, aluminum, and stainless steel

- Coil width: customizable between 150mm to 300mm

- Material thickness: 0.4mm – 1.2mm

- Decoiler can be manual or hydraulic

2. Rolling Forming Station

- Composed of multiple precision roller stands (10–14 stations depending on profile complexity)

- Rollers made of GCr15 hardened steel, surface polished and chrome-coated

- Chain-driven or gear-driven for efficient power transmission

- Forming speed: up to 25m/min

3. Hydraulic or Servo Shearing Unit

- Profile cutting controlled by PLC for exact length control

- Blade material: high-speed tool steel for longevity

- Cutting tolerance: ±1mm

4. PLC Control System

- User-friendly HMI touch screen interface

- Recipe storage for different snow guard profiles

- Length, quantity, and batch parameters can be preset

- Emergency stop, fault alarms, and maintenance reminders

Applications of Snow Guard Profiles

The metal profiles produced by the Snow Guards Rolling Machine are widely used in various roofing systems to enhance safety and compliance with building codes. Common application sectors include:

- Residential homes in snowy climates

- Commercial buildings with metal roofing

- Industrial warehouses and storage facilities

- Public facilities like schools, hospitals, and train stations

These profiles are essential in areas that experience heavy snowfall, ensuring the controlled melting and drainage of snow without risk to people or property.

Customizable Profile Designs

We understand that roof slope, region, and building structure all affect the design of snow guards. That’s why our machine supports custom profile tooling to meet your unique requirements. Whether you need standing seam-compatible guards, snap-on types, or mechanically fastened snow rails, we can engineer the perfect forming rollers for your design.

Why Choose Our Snow Guards Rolling Machine?

- Precision Manufacturing – Get consistent output that meets strict quality standards

- Customization Available – We support unique designs and integration with existing lines

- Easy Operation – Operators can master the machine quickly with minimal training

- After-Sales Support – Remote technical support, spare parts, and installation guidance included

- Export-Ready Configuration – CE, UL, or local certification available on request