When discussing metal roofing solutions, two products dominate the conversation: the R panel roofing sheet and the AG panel roofing sheet. Both offer durability, weather resistance, and long service life, but their designs make them particularly suitable for different environments. In fact, the choice between these two profiles often comes down to whether the project is industrial or agricultural in nature. At the same time, behind every reliable roofing sheet lies a well-engineered roofing sheet making machine, which enables manufacturers to supply these panels at scale.

R Panel Roofing Sheet in Industrial Applications

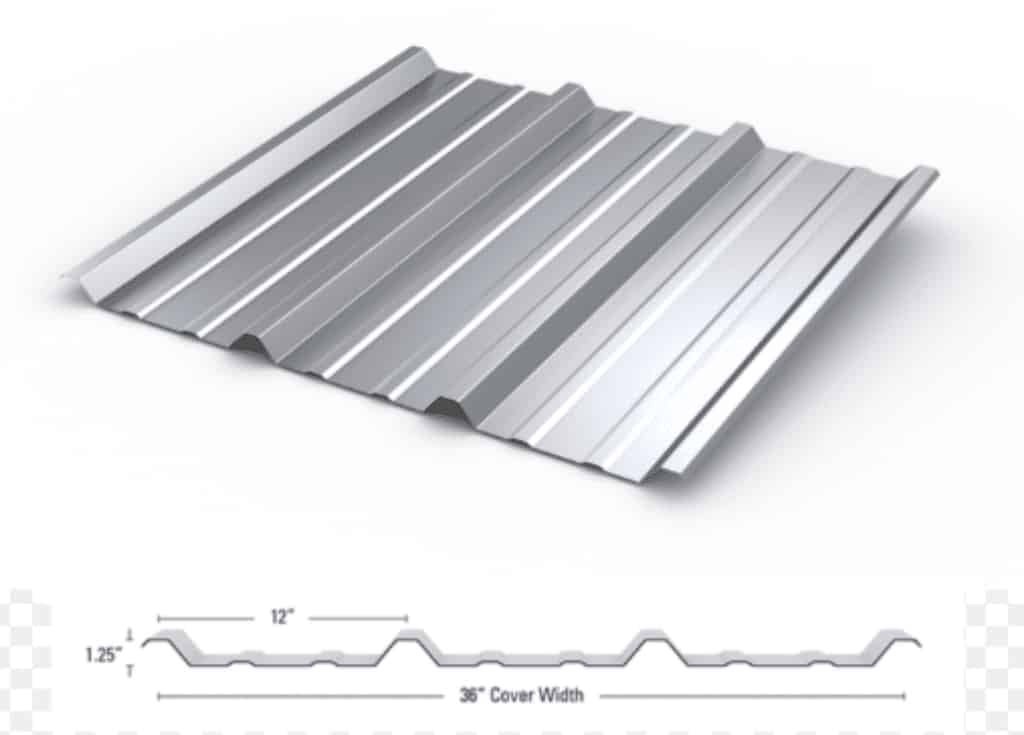

The R panel roofing sheet is widely recognized in the industrial and commercial sectors. With ribs measuring 1.25 inches in height and spaced 12 inches apart, this profile delivers strength and span capacity that lighter alternatives cannot match. Combined with its standard 26-gauge steel thickness, R panels provide the rigidity needed to cover wide spaces without excessive structural support.

This is why you will often see R panel roofing sheets on warehouses, factories, workshops, and steel-framed commercial buildings. These facilities require roofing materials that can withstand heavy loads, high winds, and long spans. Choosing R panels reduces the need for additional framing, cutting down construction costs while maintaining long-term durability. Their bold, industrial appearance further reinforces the sense of stability and professionalism required in these environments.

For manufacturers, producing R panels consistently requires high precision. The accuracy of rib formation directly impacts performance on large-scale steel structures. Here is where a roofing sheet making machine becomes indispensable. Advanced roll forming lines ensure each R panel has the correct profile, consistent gauge, and uniform coating, guaranteeing that industrial clients receive panels that meet stringent quality standards.

AG Panel Roofing Sheet in Agricultural Applications

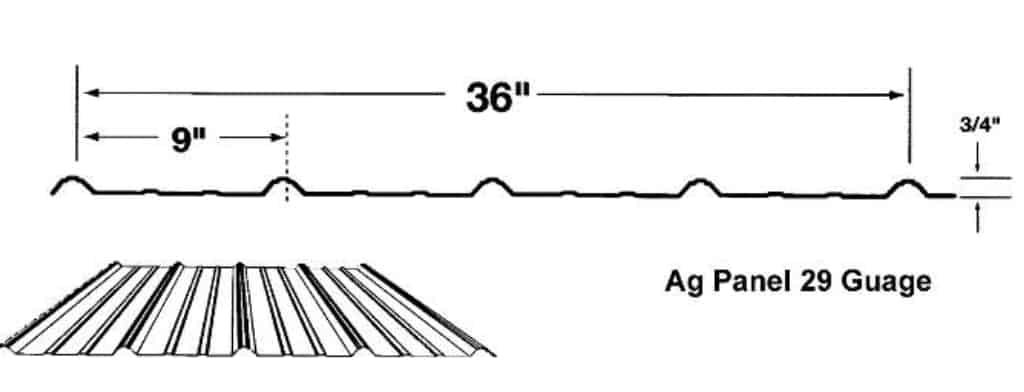

The AG panel roofing sheet was originally developed for the agricultural market, and it continues to be a favorite choice among farmers, ranchers, and rural property owners. With ribs of 0.75 inches high and 9-inch spacing, AG panels offer a lighter, more versatile profile compared to R panels. They are commonly manufactured in 29-gauge steel, making them easier to handle and more cost-effective for smaller-scale projects.

You’ll find AG panels on barns, stables, storage sheds, and even residential garages. Their modest rib design provides adequate strength for shorter spans while maintaining a subtle appearance that blends well with traditional wooden or post-frame construction. For homeowners, AG panels offer a practical and affordable roofing solution that balances durability with budget-conscious decisions.

Just like with R panels, manufacturing AG panels requires precision to maintain consistent rib height and spacing. A modern roofing sheet making machine allows producers to shift production between AG and R profiles with minimal adjustments, giving them the flexibility to serve both the agricultural and residential markets effectively.

Cost and Practical Considerations

One of the most important distinctions between R and AG panels lies in cost. Because R panels are thicker and use more steel, they are generally 10–15% more expensive than AG panels. This price difference makes sense when you consider their intended applications. For large-span industrial buildings, the strength of R panels justifies the added expense. For smaller agricultural or residential structures, AG panels provide excellent value at a lower cost.

Manufacturers, however, can benefit from producing both profiles. By using a versatile roofing sheet making machine, they can target multiple customer segments, from industrial contractors to farmers, without needing separate production lines. This versatility ensures maximum return on equipment investment and opens the door to wider market reach.

The Role of Roofing Sheet Making Machines

While end users often focus on which panel suits their project best, suppliers and distributors must consider how to produce these roofing sheets efficiently. A high-speed roofing sheet making machine is the backbone of this process. It not only ensures accuracy in forming but also allows for automation, consistent quality control, and scalable production.

With such a machine, manufacturers can confidently offer R panels for industrial clients and AG panels for agricultural markets. The ability to switch between profiles based on demand helps suppliers stay competitive and responsive to customer needs. Moreover, the advanced coating and cutting systems integrated into modern machines ensure that every sheet leaving the factory is ready for immediate installation.

Conclusion

The R panel roofing sheet and the AG panel roofing sheet each serve vital roles in today’s construction industry. R panels excel in industrial and commercial environments where strength and span capability are paramount. AG panels, on the other hand, shine in agricultural and residential settings, offering affordability and versatility.

For suppliers and contractors, the real advantage lies in having the right equipment. A reliable roofing sheet making machine enables manufacturers to produce both profiles with precision and efficiency, ensuring they can meet the diverse needs of the market. By understanding where each roofing sheet performs best—and by investing in the technology to produce them—businesses can maximize opportunities across industrial, agricultural, and residential sectors.