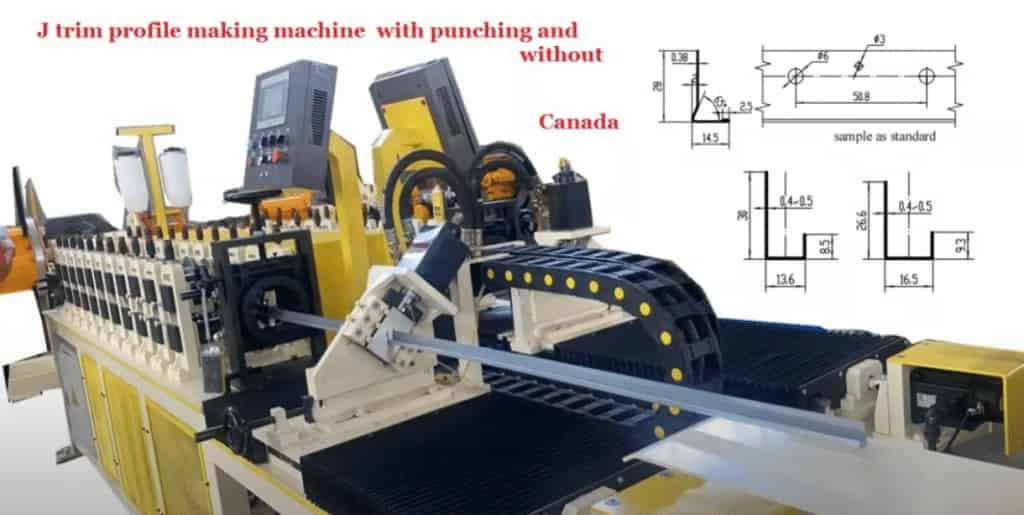

The J trim rolling forming machine is a specialized piece of equipment designed to produce precise J-shaped metal profiles widely used in construction, roofing, and siding projects. Known for its versatility and high-speed operation, this combined type machine can produce multiple sizes and styles of J trim profiles to meet diverse market demands.

In many regions, especially North America, J trim profiles are essential for finishing the edges of metal panels, vinyl siding, and roofing sheets. The J trim rolling forming machine offers manufacturers an efficient and cost-effective solution for producing these components at scale, ensuring a smooth fit and clean finish for building projects.

Combined Type – Supporting Three Production Modes

One of the most valuable features of this J trim rolling forming machine is its combined design that supports three different production configurations:

With Punching – Ideal for creating perforated J trims that allow ventilation or drainage.

Without Punching – For solid J trims that provide a clean edge finish without openings.

Multiple Sizes via Spacer Adjustment – The machine allows quick changes between sizes by simply adjusting the spacer system, without the need for complete tooling replacement.

This adaptability means that a single machine can serve multiple product requirements, reducing equipment investment and floor space while increasing operational flexibility.

Popular Profiles in the Canadian Market

The profiles produced by this J trim rolling forming machine are particularly popular in the Canadian market, where J trims are widely used in siding installation and metal roofing applications. The precise dimensions and consistent quality achieved by this equipment meet the high standards expected in North American construction industries.

By supplying popular sizes that match Canadian building codes and market preferences, manufacturers can expand their customer base and capture long-term supply contracts with local distributors and construction companies.

One Machine for Two Profiles

Another key benefit of the combined type J trim rolling forming machine is its dual-profile capability. With proper configuration, one machine can produce two distinct J trim profiles, either in different widths or styles, depending on customer demand.

This capability offers significant cost savings for manufacturers, as it eliminates the need to invest in multiple separate production lines. It also streamlines operations by allowing fast changeovers between profiles, enabling flexible production scheduling and faster response to market orders.

High-Speed Output – 45 Meters per Minute

In today’s competitive manufacturing environment, production speed is a major factor in profitability. The J trim rolling forming machine achieves a high output speed of up to 45 meters per minute without compromising profile accuracy.

This impressive speed is made possible by:

Precision roll tooling that shapes material with minimal friction and wear.

Stable forming frame structure that reduces vibration and maintains consistent profile dimensions.

Advanced motor and control systems that synchronize punching, forming, and cutting processes.

The result is a production line capable of meeting large orders quickly while maintaining consistent quality.

Double Head Decoiler for Continuous Operation

The machine is equipped with a double head decoiler, which allows operators to prepare the next coil while the current one is still running. This feature eliminates downtime during coil changes and ensures uninterrupted production.

With the double head decoiler, manufacturers can maximize uptime, improve productivity, and reduce labor costs. The system also supports various coil widths and materials, making it suitable for different J trim applications.

Technical Advantages of the J Trim Rolling Forming Machine

1. Precision Engineering

The forming rollers are CNC-machined and heat-treated for long life and consistent performance.

2. Easy Size Adjustment

Spacer adjustment makes size changes quick and straightforward, minimizing production interruptions.

3. Durable Construction

A heavy-duty frame ensures long-term stability and resistance to deformation, even under high-speed operation.

4. Low Maintenance

All moving parts are designed for reduced wear, and the lubrication system helps extend component lifespan.

5. User-Friendly Control System

An intuitive PLC touch-screen interface allows operators to control profile size, punching patterns, and cutting length with precision.

Applications of J Trim Profiles

J trim profiles are a vital finishing component in various industries, including:

Residential siding installation – Providing a neat border for vinyl and metal siding panels.

Metal roofing systems – Protecting panel edges and improving water drainage.

Industrial cladding – Offering a clean, protective edge finish on large-scale projects.

Interior wall panels – Creating a professional and safe edge detail in commercial spaces.

With the J trim rolling forming machine, manufacturers can produce the exact profiles needed for these applications while maintaining high efficiency.

Meeting International Standards and Custom Requirements

The J trim rolling forming machine can be customized to meet different regional standards, including those in North America, Europe, and Asia. Whether the requirement is for specific punching patterns, unique material thicknesses, or custom profile dimensions, the equipment can be adapted to deliver the required specifications.

This flexibility ensures manufacturers can serve both domestic and export market s effectively, making the machine a long-term asset for growing businesses.