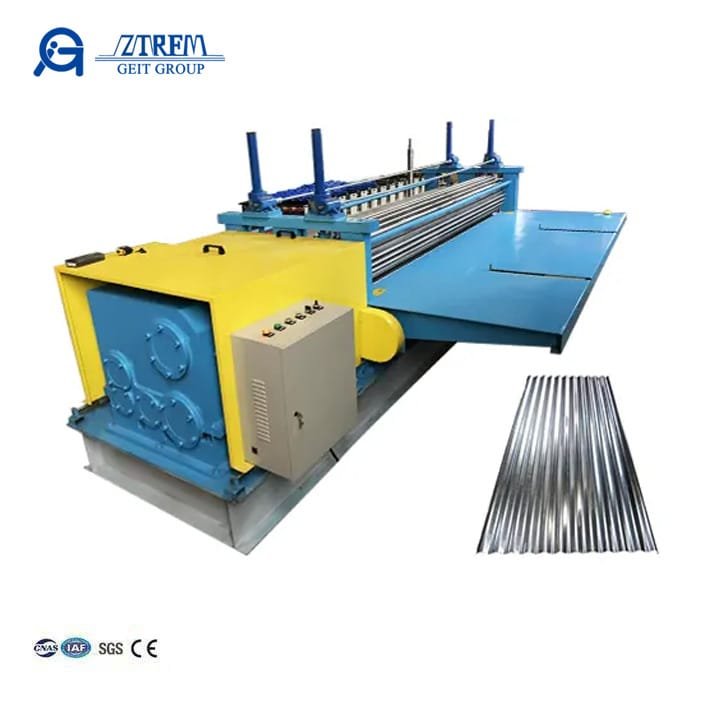

Thin material galvanized steel barrel type steel roof sheet making machine

Creating a thin material galvanized steel barrel-type roof sheet requires specialized equipment known as a roll forming machine. This thin material galvanized steel barrel type steel roof sheet making machine is designed to process metal sheets into the desired shape and profile.

Quality Control:

Various sensors and controls monitor the process for consistency and quality.

Considerations:

Material Thickness: Ensure that the machine is suitable for processing thin galvanized steel sheets.

Roll Forming Profile: Customize the roll forming stations to achieve the specific barrel-type profile.

Speed and Output: Adjust machine parameters for the desired production speed and output.

Before purchasing or operating such a machine, it’s essential to consult with the manufacturer for detailed specifications and customization options based on your specific requirements.

Fast Speed:the machine speed is about 20-60 pieces/min,if material very thin,can make 3 pieces at the same time.

Forming Thin Material:Thin material such like 0.12-0.3mm thicknessis very popular in Africa market, so this machine is very popular in that market.

FAQ:

1. Why some sheet panel need the round wave machine while some sheet panel machine need the cold roll forming machine?

The difference is that, the sheet panel made by the round waveroofing sheet machine is much thinner and with hardness up to 550 Mpa.The thickness range is: 0.2-0.6. But the thickness of the cold roll forming machine coil is 0.3-1.0mm as usual.

2. Which machine with higher capacity between the round wave machine and cold roll forming machine?

The capacity of the round wave machine and cold roll forming machine is more or less similar capacity, the round wave machine can press several pieces of the sheet at one time.

Common Problem

Because the raw material is relatively thin, the two ends of the product are prone to rebound, but our machine gear shaft has more processing procedures than others, so this problem can be effectively avoided

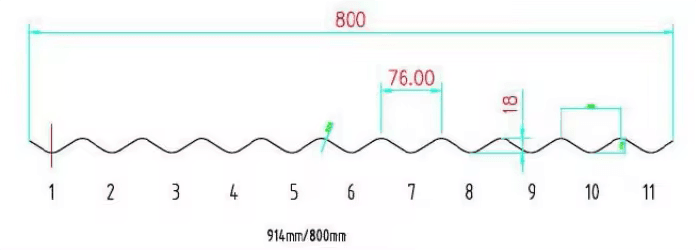

Profile drawing for reference:

USually this machine only produce corrugated sheet ,this is the drawing as followed:

Barrel Corrugated Roof Sheet Making Machine

Raw Material: PPGI,PPGL

Material thickness:(0.12-0.3 mm)

Material Of Rollers: High grade 45# forged steel

Forming stations: 2 sets (4 pieces)

Roller diameter: 450mm

Forming speed: 2-3 seconds per piece

Voltage: 380V/50HZ/3P (as requested)

Main motor: 7.5 KW