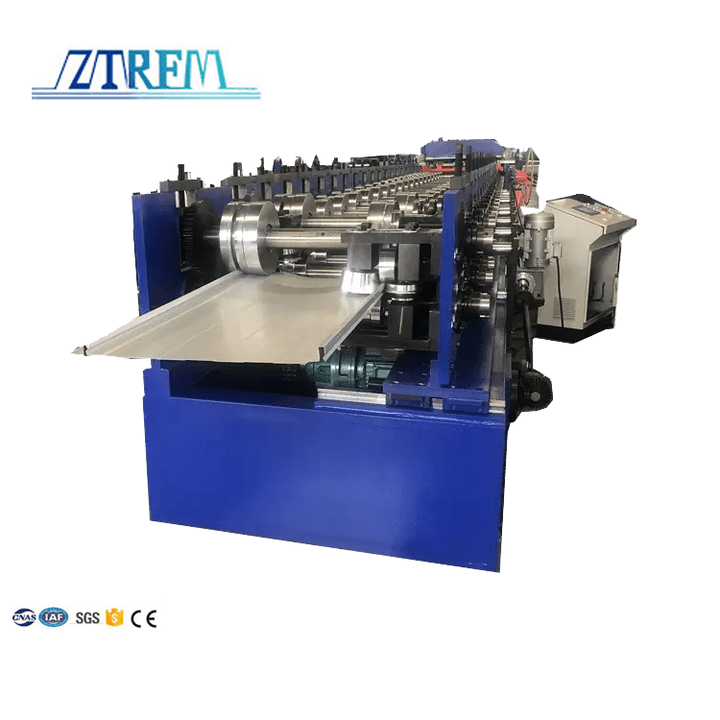

Aluminum Alloy PIR Insulated Great Wall Panel Machine

Zhongtuo’s Aluminum Alloy PIR Insulated Great Wall Panel Machine is a fully automated, high-output production line engineered to manufacture aesthetically appealing and thermally efficient sandwich wall panels. With its modular construction and precision roll forming technology, the machine delivers a seamless combination of strength, insulation, and surface finish—ideal for modern industrial buildings, warehouses, and prefab houses.

Product Overview

The Aluminum PIR Great Wall Panel is a type of exterior insulated siding panel with a distinctive linear design inspired by the iconic Great Wall. Crafted from durable aluminum alloy and featuring a rigid PIR (Polyisocyanurate) core, the panel offers:

Excellent thermal insulation for energy-saving applications

Waterproof and UV-resistant performance in all climates

Visually seamless installation with hidden fasteners

Modern aesthetics suitable for commercial and residential use

This machine supports batch production with custom lengths, thickness options, and an output speed of 6–8m/min.

Applications of Finished Panels

Enclosure walls for industrial buildings and factories

External wall coverings for barns, logistics warehouses

Roof and side panels for sunrooms, pavilions, and light steel structures

Prefabricated housing and mobile office buildings

Main Components of the Production Line

Main Roll Forming System

Dual forming stations for upper and lower plates

5-ton hydraulic decoiler with double trolley support

Max speed: 10m/min

Power: 7.5kW with frequency control

Pre-Heating Device

Hot-air system to preheat panels (25–35°C adjustable)

Digital temperature control

Ensures optimal foam bonding

High-Pressure Foaming Machine

Dual-component PU/PIR high-pressure injection

Smooth and consistent core filling

24m Double Track Laminating Conveyor

Adjustable foaming width up to 900mm

60mm thick 16Mn chain plates for durability

Speed adjustable 3–10m/min

Automatic Band Saw Cutting Machine

Tracks the moving panel for precise cutting

Equipped with vacuum and return mechanisms

Technical Specifications

| Parameter | Value |

|---|---|

| Panel Width | 1250mm |

| Panel Thickness | 30mm (customizable) |

| Core Material | PIR / PU foam (40–60kg/m³) |

| Production Speed | 6–8m/min |

| Heating Temperature | Max 60°C |

| Total Line Length | ~90m |

| Power Requirement | ~160kW |

| Track Conveyor Length | 24m |

Why Choose Zhongtuo?

Turnkey factory solutions from layout to commissioning

Customization available for width, profile, and foam density

Remote support and on-site training included

High ROI from energy-efficient, long-lasting machines