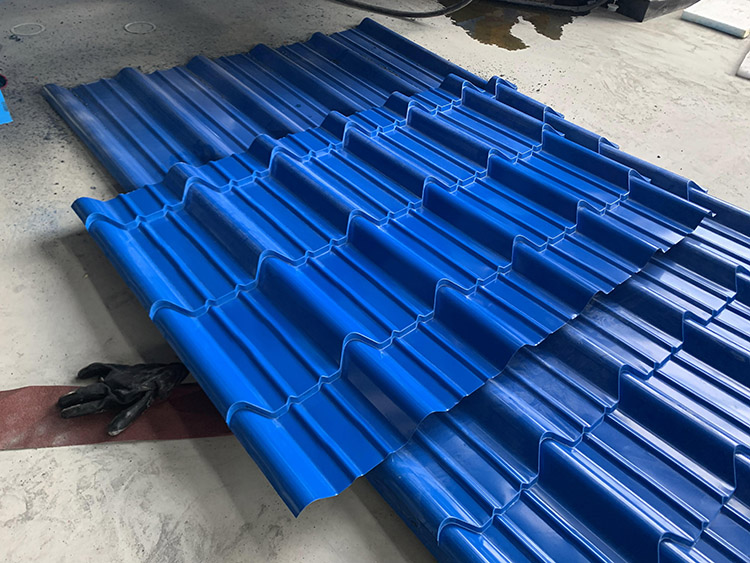

High Speed Step Glaze Roofing Tile Roll Forming Machine

A high-speed metal glaze roofing roll forming machine is a specialized equipment used for manufacturing glazed metal roofing tiles. It efficiently processes metal coils through a series of rollers to form the desired tile profile. The glazing process adds both aesthetic appeal and protective properties to the tiles. With features like high-speed operation, precision forming, and automated controls, this machine ensures consistent quality and productivity in producing glazed metal roofing tiles.

The advantage of High Speed Glaze Roofing Tile Roll Forming Machine

1. High speed: Gearbox transmission enhances speed up to 10m/min, reducing pressing and cutting durations.

2. Adopt mold cutting, the product exhibits lace-type edges, resulting in aesthetically pleasing tiles.

3. Hydraulic decoiler and auto stacker minimizes labor requirements during operation, improving efficiency.

Take the following drawing profile for example:

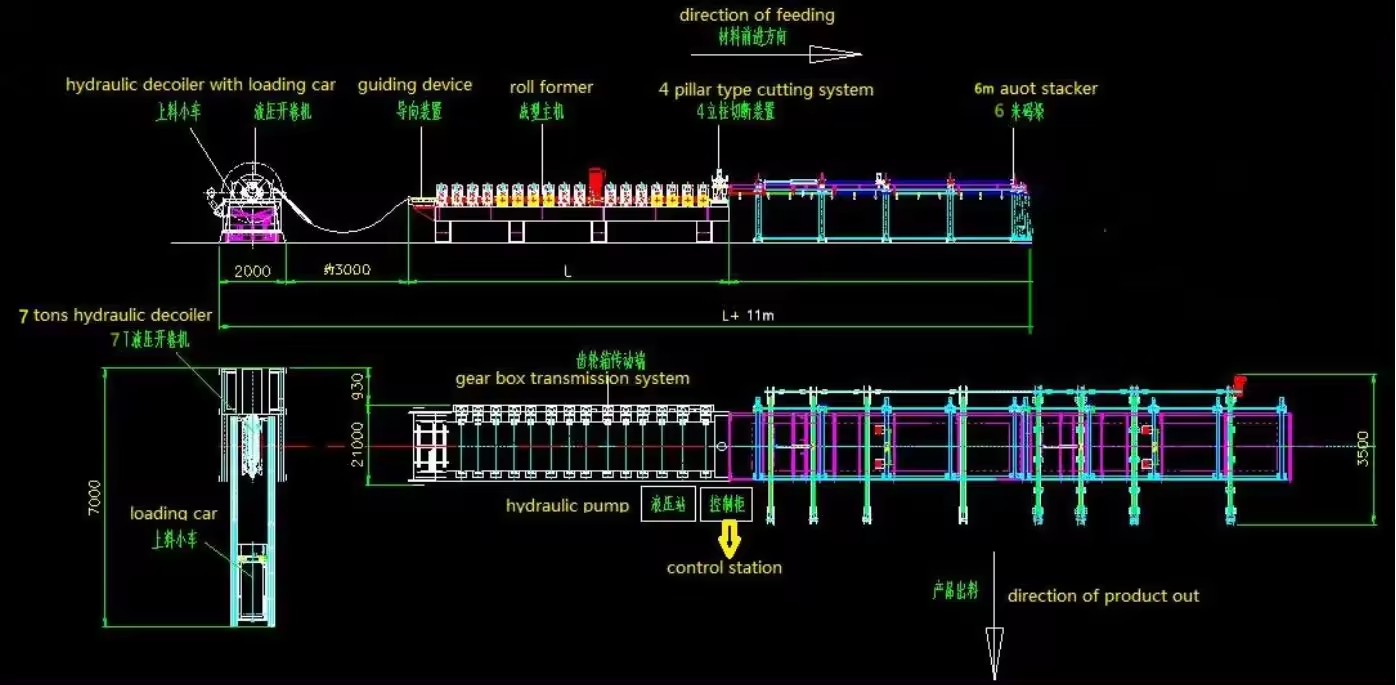

The working flow:

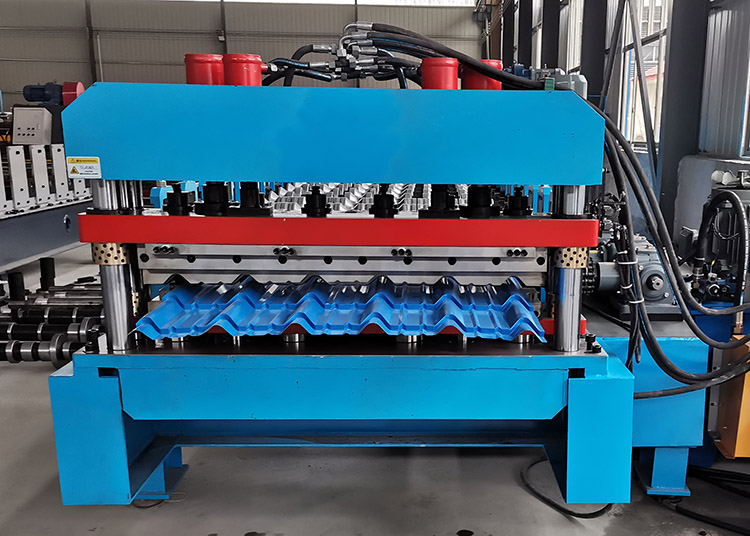

High Speed Step Tiles Roll Forming Machines Glaze Roofing Tile Roll Forming Machine

Formed Material: PPGI

Thickness: 0.32-0.8mm

Machine Frame: 400# H Steel Frame Welded

Machine Structure: Vertical Arch Frame Structure

Material Of Rollers: 45# Steel,Chromed Treatment (Cr Thickness:0.05 Mm)

Forming stations: 18 stations

Diameter of shafts: Φ80mm

Material of shafts: 45# Steel Tampering Treatment, Prevent Deformed And Improve The Hardness

Forming speed: About 0-10m/min

Voltage: 380v 50hz 3phase Or As Request

Work power: 11 kw ( gear reducer and servo motor driving)

Cutting blade material: Cr12 with quenched treatment

Cutting type: Hydraulic cutting

Hydraulic decoiler

1. Capacity: 5T

2. Coil diameter: 450-550mm

3. Coil outer diameter: 1500mm

4. Coil width: 1250mm(as customers’ request)

5. Hydraulic power: 5.5kw

Feeding Part

1. Protective Rubber Rollers: Safeguard the surface of raw materials from damage.

2. Convenient Handwheel Adjustment: Easily adapt for feeding various thicknesses of raw materials.

3. Adjustable Platform Width: Handwheel-operated platform width adjustment, featuring internal bearings to shield the steel sheet edges.

Roll Forming System

1. Material Of Rollers: 45# Steel,Chromed Treatment (Cr Thickness:0.05 Mm), Anti-Corrosion,Increase Hardness, Ensure The Precision And Good Abrasion Performance.

2. Material of shafts: 45# Steel Tampering Treatment, Prevent Deformed And Improve The Hardness

3. Forming stations: 16 stations

4. Diameter of shafts: Φ80mm

5. Machine Structure: Vertical Arch Frame Structure

Transmission

1. Gear Box Transmission (Bevel Gear Inside)

2. Material Of Gear: 20 Crmnti

3. Material Of Gear Box: Iron Casting

4. The connection between gear boxes are chains

5. Gear box will connect with the rolling station one for one

6. Advantage: can improve the speed directly after cutting

Hydraulic Cutting Device

1. Blade material: Cr12, with quenched treatment

2. Hydraulic power: 7.5kw

3. Cutting tolerance: ±1mm

4. With fan cooling on the oil pump

PLC control system

1. Control system: PLC

2. PLC brand: Delta from Taiwan

3. Frequency converter brand: Delta from Taiwan

4. Encoder: Omron

5. Function: Automatic control the length and quantity