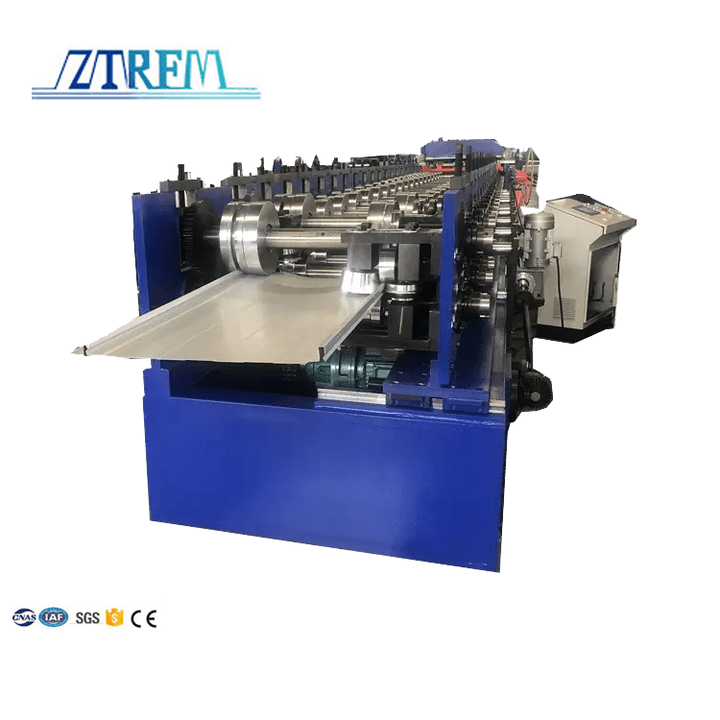

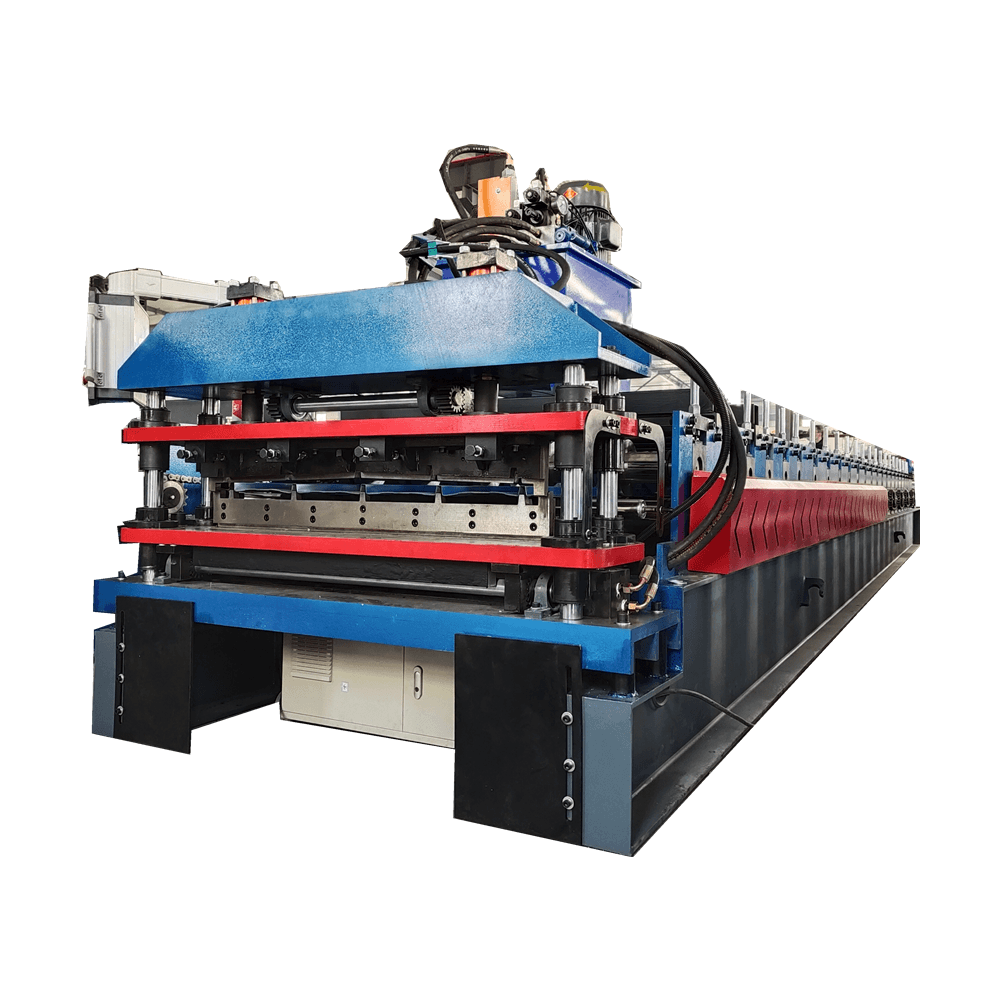

Rain Gutter Making Machine Roll Forming Machine

Rain gutter roll forming machines are specialized equipment used for manufacturing rain gutters, which are essential components of a building’s roofing system. The machine is widely used in steel or aluminum sheet cold form industries. It can form rain gutter profiles according to customer’s requirement continuously, automatically cut to length. The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production.It has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good appearance and so on.

The pictures for the finished product of gutter roll forming machine:

Profile drawing for reference:

The application of the product rolled by rain gutter roll forming machine:

Formed Material: PPGI,GI,AI,GL

Raw material thickness:0.4–0.8 mm(customized)

Roller station:18 rows(As your requirement)

Diameter of shaft: 70mm solid shaft

Material of rollers:45# steel, hard chrome plated on the surface

Machine body frame:350 H steel

Drive:Chain transmission

Cutter: cr12mov material, no scratches, no deformation

Motor Power: 5.5KW

Hydraulic system power: 5.5KW

Voltage: 380V 50Hz 3Phase(As your requirement)

Forming Speed:12-15m/min

1.Guide feeding device

The feeding rollers which we use is stainless steel.

And the ball bearing roller is inside the feeding rollers which is very convenient to feed the steel coil into it.

2.Main roll forming device

Base Frame Structure: 350 H-beam welded

Connect Bar: Diameter 25mm galvanized steel rod

Forming speed: 12-15m/min

Feature: Ensure stability , precision and lifetime.

3.Gear and chain transmission device

In order to keep the product shape and precision, chain dive, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working.

4.hydraulic shearing device

Frame Structure: steel plate welded and screwed

Platform Function: easily to pre-cut the plate while change different steel coils

The cutting Blade: Cr12Mov