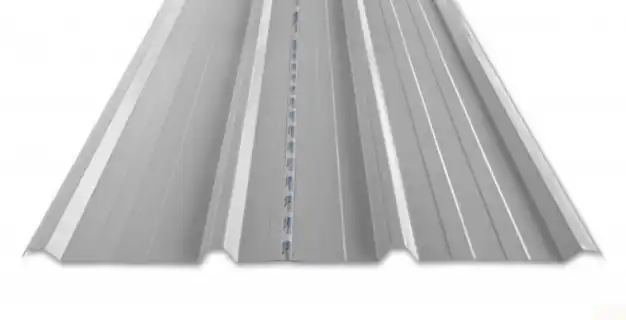

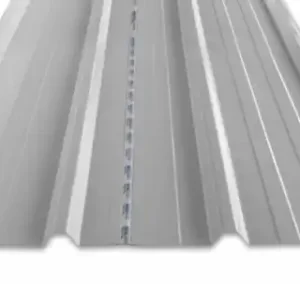

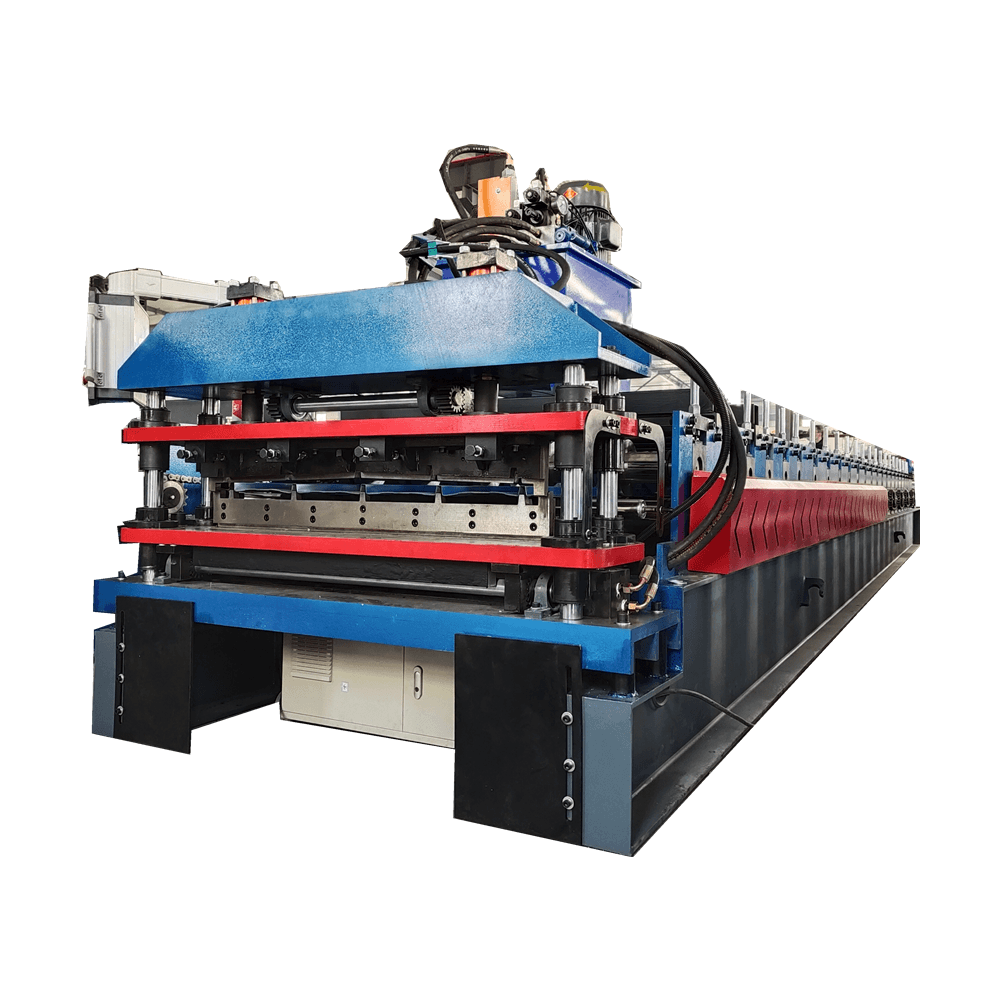

Tr4 roofing sheet making machine

Tr4 roofing sheet machine is used to produce tr4tr5tr6 roof sheet, which has light weight, anti-corrosive, fireproof, high strength and beautiful appearance and rich color. This machine can plastic deform metal materials at room temperature without heating and it is widely used in the construction of workshop, warehouse and carport.

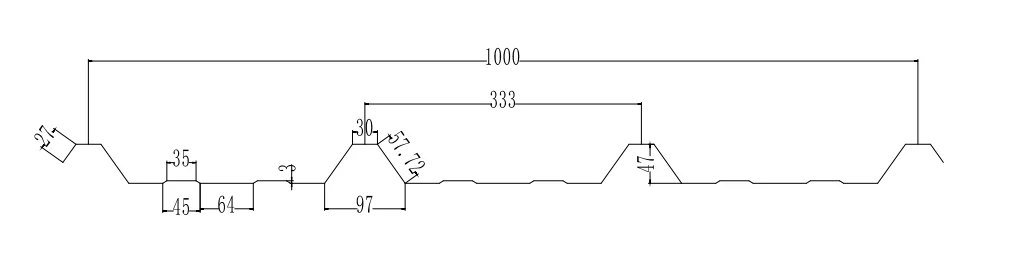

Some profile drawings for reference:

Raw Material: PPGI,PPGL

Material Thickness:24/26 Gauge (0.4-0.6 Mm)

Machine Frame:350mm H Beam Structure, with 18mm welded steel middle support plate.

Roller Material :45# steel, chromed on the surface

Roller Stations :22 Rows

Diameter Of Shafts:Φ80mm solid

Material Of Shafts: High Grade 45#,with Heat Treatment

Forming Speed:15 M/Min

Voltage:380v/50hz/3p (As Requested)

Transmission Way: By 1 Inch Chain (Double Chains)

Main Motor:5.5 KW

Cutting Blade Material:Gcr12 quenched treatment

Cutting Type: hydraulic post cutting

Driving Method: By pillar type Cylinder

Work type: passive decoiler

Capacity:5 tons

Coil inner diameter:450-550mm

With manual brake and hand wheel to prevent the deposition of material.

Hand wheels on both sides: adjust the feeding width.

Three supports and one pressure, three rows of rolling rubber rollers: prevent the scratch on the material surface.

Feeding port has chain links, nylon brackets and insert screws to protect the steel from scratches.

The upper nylon plate has a partial missing, convenient to observe the position of the steel when feeding.

Machine Frame:350mm H Beam Structure, with 18mm welded steel middle support plate.

Roller Material :45# steel, chromed on the surface

Roller Stations :22 Rows

Diameter Of Shafts:Φ80mm Solid

Material Of Shafts: High Grade 45#, with heat treatment

Forming Speed:15 M/Min

The shaft and roller are arranged by the key grooves to prevent the linear speed of the shaft from being inconsistent with the roller.

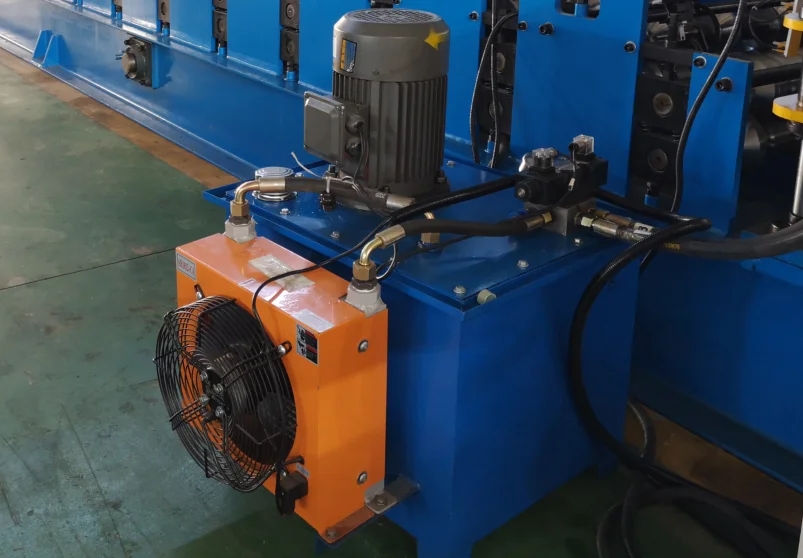

Cutting Type: hydraulic post cutting

Hydraulic station motor:5.5KW

Hydraulic oil:46# hydraulic oil

Main components: hydraulic tank, hydraulic oil pump, hydraulic pipes, electromagnetism valve

PLC brand :Delta PLC, and transducer and touched screen

Encoder brand :Omron

Electrical components :Schneider

Operating language :English and Chinese (or as requested)

You can set the orders on this part, changing product length and quantity, it is really easy to operate, and there are aviation plugs to make it much easier to install the ibr roll forming machine while it arrived.