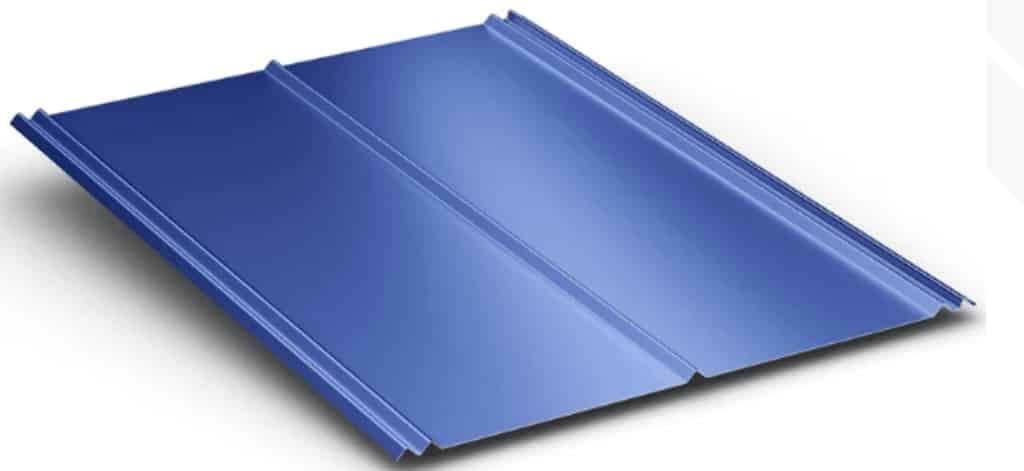

The 5V crimp roof panel machine is a high-performance solution designed for manufacturing 5V metal roofing panels with exceptional accuracy and structural integrity. Initially developed for agricultural roofing needs, the 5V profile has gained wide acceptance in residential and light commercial applications due to its simple, attractive design and outstanding durability. Whether mounted permanently in a fabrication shop or configured as a mobile unit for on-site work, this machine delivers consistent, high-quality output under all conditions.

Versatile Panel Forming for a Range of Applications

5V crimp panels are well-known for their ability to withstand harsh weather, making them ideal for use in both rural and urban environments. This machine produces smooth, precisely formed metal sheets that perform reliably in long-term installations. From barns and sheds to homes, warehouses, and public facilities, these panels are trusted for their combination of performance, affordability, and visual appeal.

Whether you’re supplying panels for residential roofing, agricultural structures, or commercial exteriors, the 5V crimp panel machine gives you the production capacity and flexibility to meet a variety of project demands.

Key Benefits of the 5V Crimp Roof Panel Machine

Hydraulic Drive & Cutting System

Equipped with a front hydraulic scissors shear, this machine ensures clean and efficient cutting after panel forming. The hydraulic-powered drive system guarantees consistent forming pressure and smooth panel feed, contributing to higher precision and minimal material waste.

Adjustable Panel Width Settings

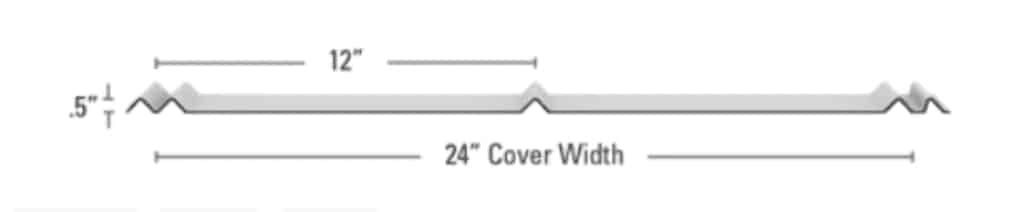

Offering adjustable forming widths from 12″ to 20″, the machine accommodates various coil sizes and project specifications. When using standard 27.5″ coil stock, the machine outputs panels with a finished width of 26″, which overlaps to provide 24″ of effective coverage—ideal for weatherproof roofing systems.

Robust Roll Forming Structure

The machine is constructed with 14 forming stages that shape the metal into the 5V profile with accuracy and consistency. The 416-grade stainless steel forming rollers are hardened to withstand continuous use and reduce wear over time. These high-grade rollers ensure minimal maintenance while maintaining panel quality.

Technical Specifications

Drive Type: Hydraulic drive with #40 chain

Power Unit: 3 HP electric-hydraulic system, 110V, single-phase with 16 cu in drive motor

Cutting System: Front-mounted hydraulic scissors shear with shear dies

Speed: Up to 40 feet per minute (FPM)

Adjustable Panel Width: 12″ to 20″ (standard output: 26″ panel width for 24″ coverage)

Roller Material: Hardened 416 stainless steel

Machine Frame: Heavy-duty welded tubular steel structure for stability

Control System: Push-button RUN/JOG controls at both entry and exit

Length Control: Integrated limit switch for accurate panel sizing

Safety Features:

Panel recognition proximity switch

Power interruption safety circuit

Warranty: Backed by the industry’s most reliable warranty program

Built for Long-Term Performance in Tough Environments

This 5V crimp roof panel machine is engineered to handle rigorous use in demanding production settings. Thanks to its durable frame, stainless steel forming rollers, and high-torque drive, you can expect reliable output day after day with reduced maintenance requirements.

Its modular design also makes it easy to relocate or transport, allowing manufacturers and contractors to bring their production capabilities directly to job sites—boosting flexibility and responsiveness for fast-paced projects.