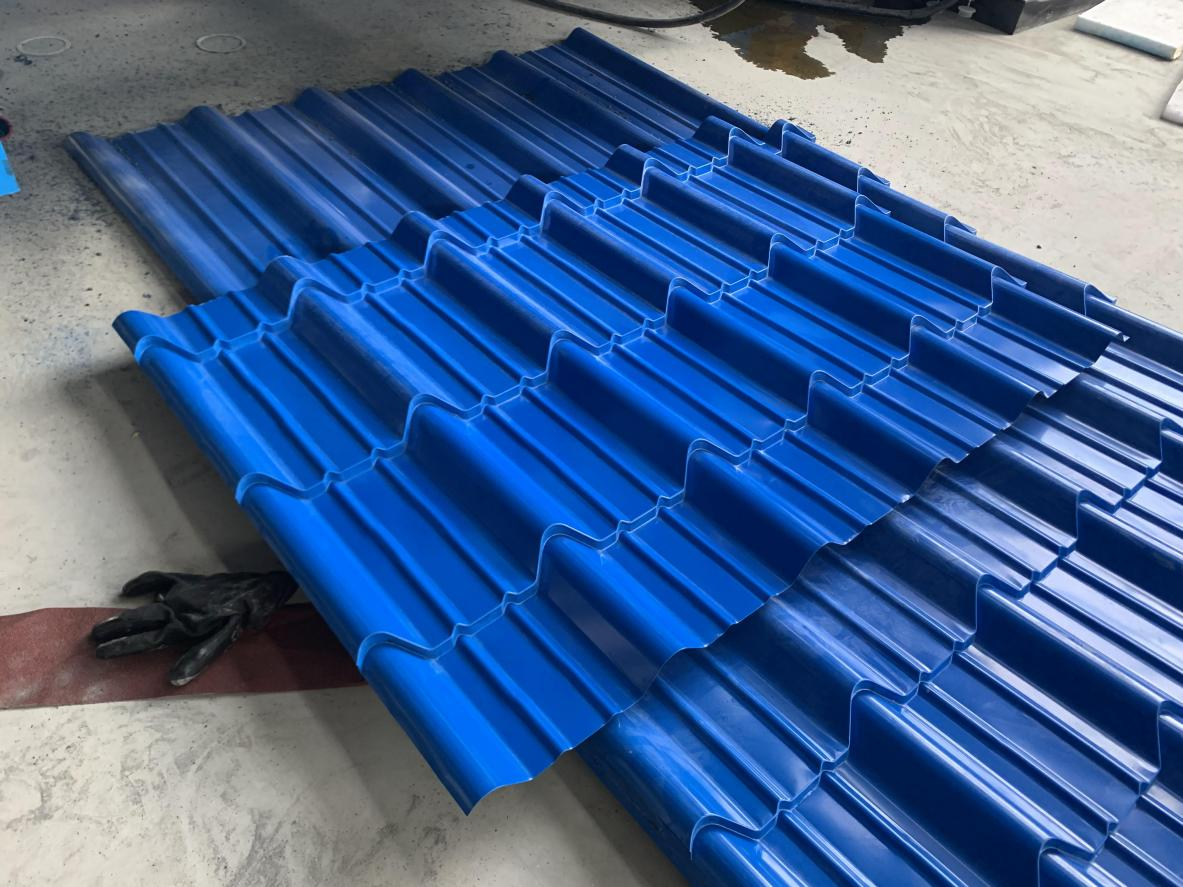

High speed glazed tile roofing sheet machine

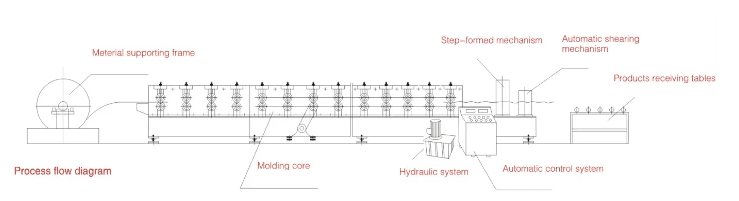

Compared with the trapezoidal roofing sheet roll forming machine, high speed glazed roof tile roll forming machine is added a set of step-formed device in front of the shearing mechanism, aimed to form the steps.

The whole production flow of the glazed forming machine:

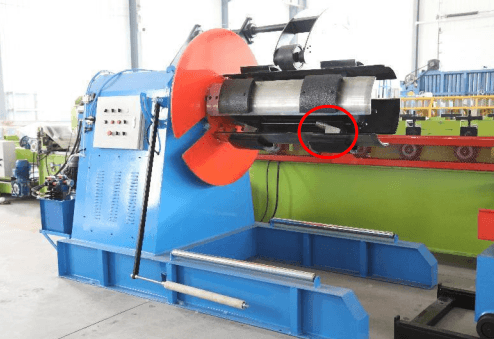

The baffle is provided with a groove, so that when the steel coil is hoisted by a sling, it can be conveniently accessed.Four circular arc arms are very steady and will keep the coil in shape.Dovetail groove type diameter adjustment mode of the decoiler is more stable and has better bearing capacity.

An active type. It is powered by the motor reducer, can automatically start or stop working according to the running speed. It can be easily operated and used by one person. Save labor.,more expensive and need more space to place the machine.

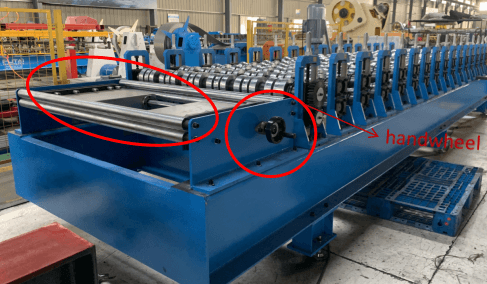

Guide Feeding Device

Two rollers of the feeding device can rotate, so that the friction between the steel and the rollers can be reduced during the feeding process and the steel surface can be avoided.The top roller also prevents the steel from warping.There are two rollers inside which also avoid material scratches.

The hand wheel on the side can be used to adjust the feed width for feeding.

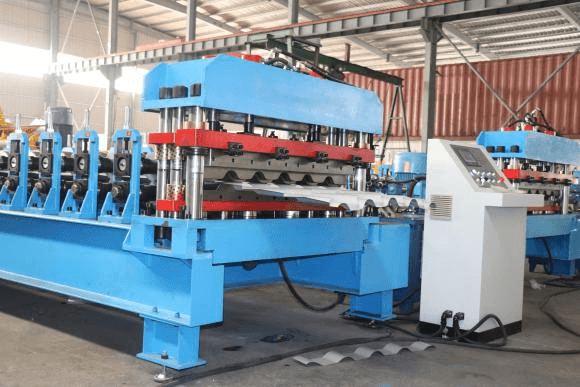

Main Roll Forming Machine of glazed tile machine:

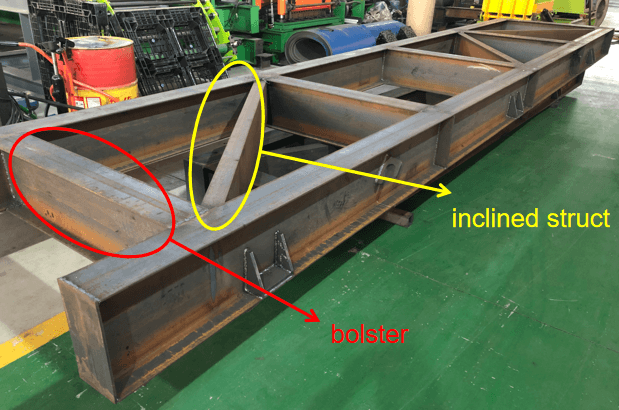

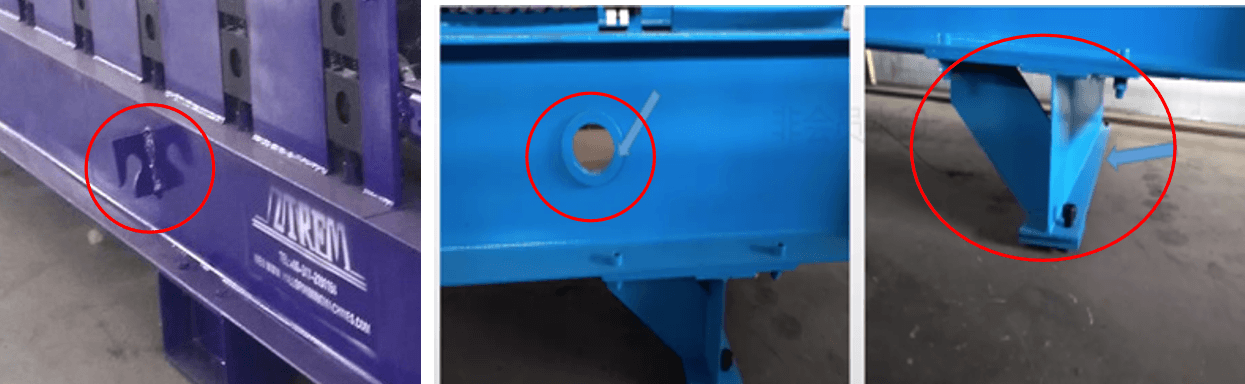

1.Our frame is welded by 350# H-shaped steel. The H-shaped frame and the design of the inclined strut and bolster increase the strength of the frame.The lifting ear, lifting hole and lifting hole are convenient for loading and unloading.

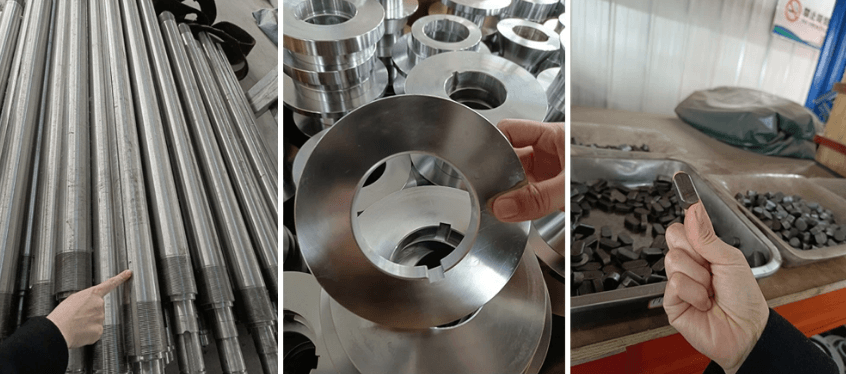

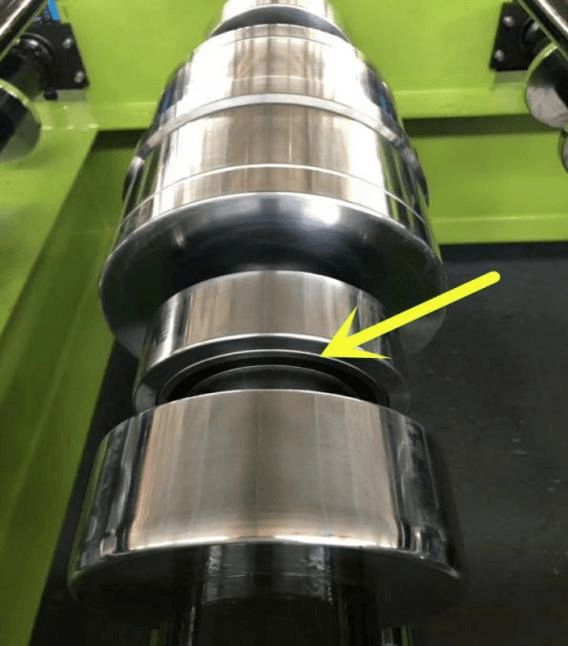

2.Our rollers are made of 45# steel with quenched treatment.The roller has high hardness, long service life.It also can prevent rust.

3.The diameter of the shaft are 80mm which can be produced according to your requirements. The material is 45# steel with tempered. Solid and not easily damaged.

4.The shaft and roller are arranged by the key grooves to prevent the linear speed of the shaft from being inconsistent with the roller, which will cause displacement.

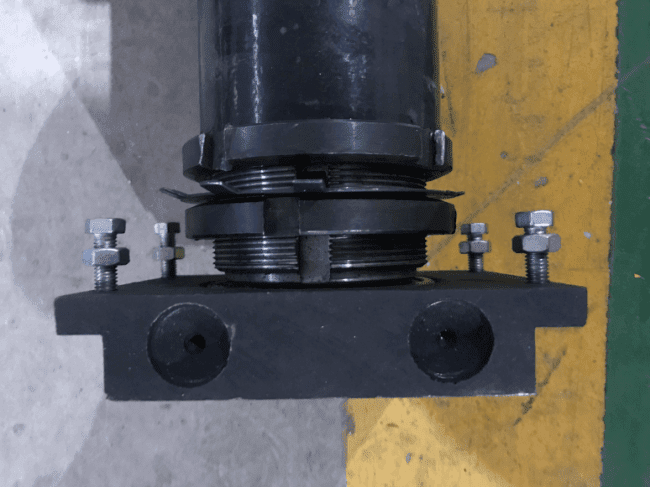

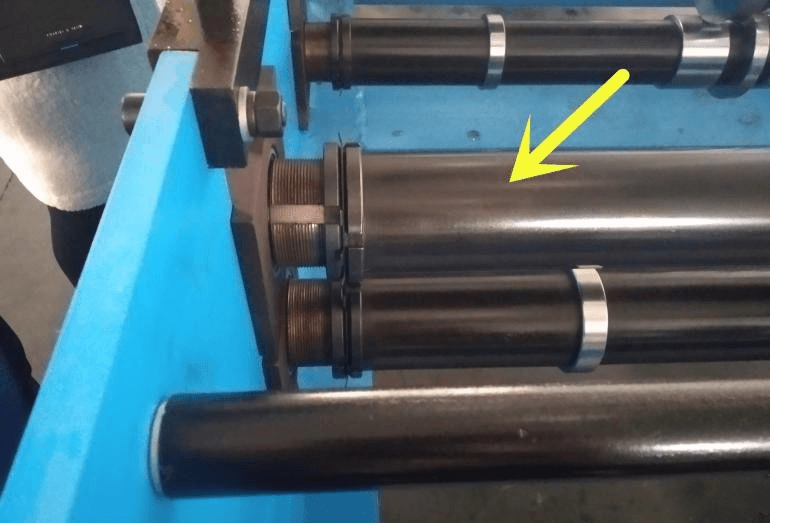

5.The design of positive and negative turnbuckles,double lock nuts ,and check mat can prevent the shaft from loosening during machine operation.

6. Spacer is made of 45# seamless steel pipe, which is strong enough to ensure the normal operation. After boiling black processing, not easy to rust.

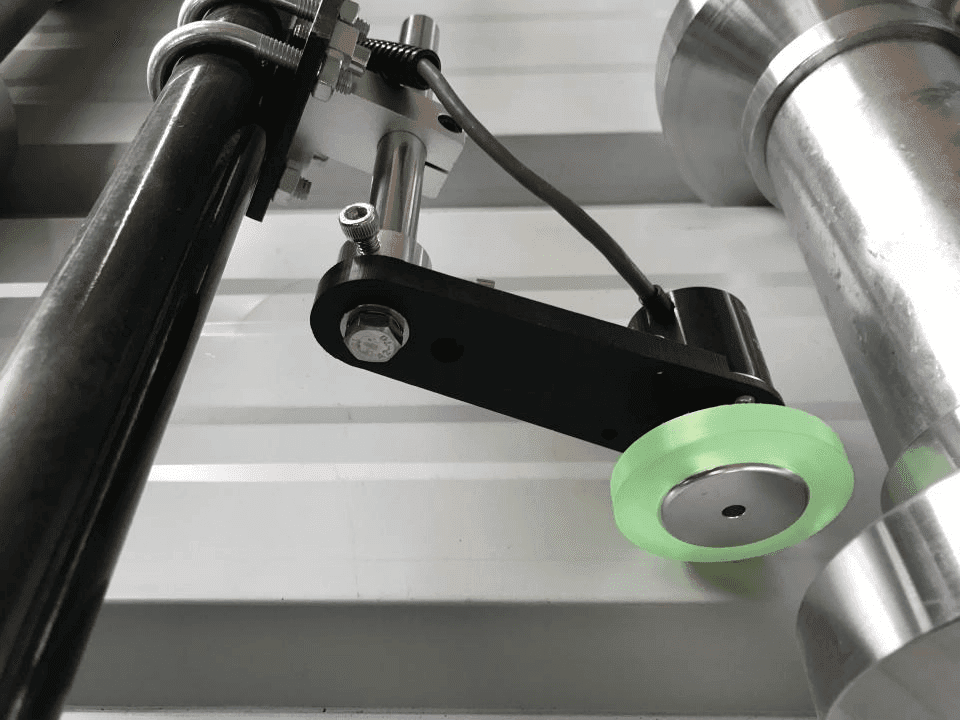

7. The existence of bearing can avoid paint scratches caused by inconsistent line speeds.

8.Shape of the first step is linear.

9.Integrated type:

Save material, no material wasted at the end, the pressing section and the cutter do not affect each other, so it is not easy to have a knife, but the length of the first section cannot be adjusted and is fixed.

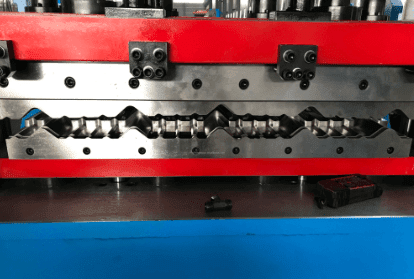

Hydraulic Cutting of the glazed roll forming machine:

The cutter blade material is Cr12 with quenched treatment.

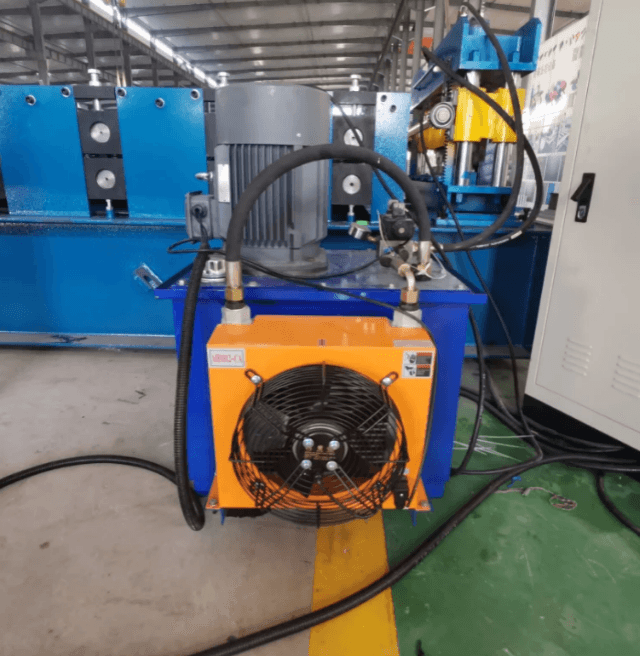

Hydraulic Station

Hydraulic Station provides the power for the shearing mechanism.We adopt the oil of 46# and large valve with high cost which is not easy to block.And the power is 5.5kw.The capacity of the fuel tank is 80 liters.We are equipped with air cooling devices to prevent the hydraulic oil from overheating and affecting the operation of the machine.The motor of hydraulic station is a Chinese standard brand with good quality and long service life.

Electric Control System

There are touch screen and manual buttons to control the movement of the machine and the length of the sheet.The language of the panel is English.We can also customize other languages according to your needs.

Equipped with internationally well-known brands such as Delta, Schneider,Siemens,if it is damaged, convenient to repair. In addition,the electronic contacts in our manual buttons are silver, which has good conductivity, accuracy and long service life.

Omron counters with accurate counting measurement and good quality. Each wire marked with a number or letter is installed neatly.

The aviation plug used to integrated these wires together is inside a box to protect it.Convenient for use. Install remote operating system of PLC,so that our engineers will debug it for you remotely when there is a problem with the machine.

Automatic stacker

Automatic stacker realizes full-automatic receiving steels to save labor.