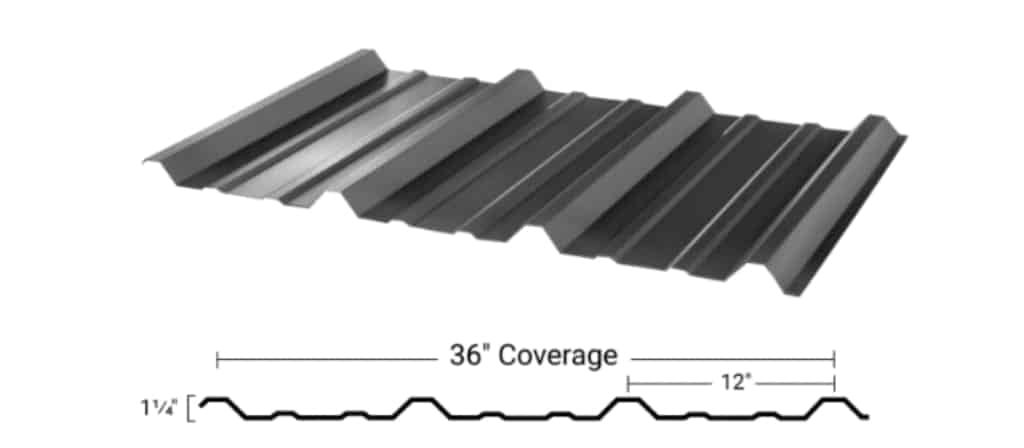

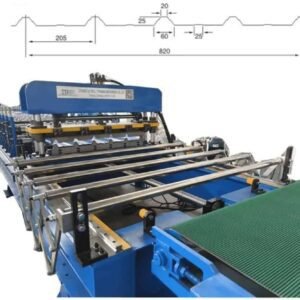

Looking for a high rib roof panel machine that delivers consistent performance, fast output, and exceptional panel quality? The HR-36 model is specifically engineered for manufacturing HR-36 style metal roof panels, known for their distinct 36-inch net coverage and 2 1/16-inch trapezoidal ribs. This configuration not only offers strength and water-shedding efficiency but also enhances the architectural appearance of any structure.

With advanced forming technology and a robust mechanical design, the HR-36 machine is the perfect solution for manufacturers producing roof panels for commercial, industrial, and architectural applications.

Modern Design for Superior Roofing Panels

The HR-36 machine creates metal roofing panels with pronounced high ribs that cast sharp linear shadows, giving buildings a clean, modern look. Whether you’re supplying materials for a warehouse, retail center, or residential development, this equipment ensures each panel is formed with structural accuracy and smooth finishes.

Key Advantages of the HR-36 High Rib Roof Panel Machine

High-Speed Panel Forming

Engineered for productivity, this high rib panel machine features an efficient drive system that supports rapid panel production. It’s built to handle bulk orders with ease, ensuring steady performance during extended production runs.

Precision Engineering

With 18 forming stations, the machine guarantees consistent profile geometry and panel dimensions. Each component—from the 45# steel rollers to the hardened transmission shafts—is selected for durability and long-term operation in demanding environments.

Hydraulic Cutting System

The built-in hydraulic shear delivers clean, burr-free cuts with a tolerance of ±1 mm. This ensures that every panel edge is smooth, safe to handle, and ready for immediate installation—saving time in post-processing.

Advanced PLC Control

Operators benefit from a user-friendly PLC interface, compatible with Delta, Siemens, or Mitsubishi systems. This programmable system simplifies the production process, increases automation, and provides flexibility to meet changing production needs.

Detailed Specifications

Material Compatibility: Galvanized steel, Pre-painted steel

Thickness Range: 0.3 mm – 0.8 mm

Decoiler: 5-ton hydraulic decoiler (manual and custom options available)

Roller Stations: 18 forming steps

Roller Material: 45# steel with heat treatment for extended wear life

Shaft Diameter: 80 mm

Shaft Composition: 45# tempered steel for added rigidity

Transmission Type: Gearbox-driven for stable power transfer

Main Motor Power: 5.5 kW

Frame Construction: 400H beam welded structure

Cutting System: Hydraulic shear

Hydraulic Power: 5.5 kW pump

Blade Material: CR12 high-carbon tool steel

Cutting Accuracy: ±1 mm

Control System Options:

PLC: Delta / Siemens / Mitsubishi

Touch Screen: Delta / Siemens / Mitsubishi

Encoder: Omron

Built for High-Volume Metal Roofing Production

The HR-36 high rib roof panel machine is specifically designed for efficiency and minimal downtime. Whether you’re scaling up production or replacing older machinery, this system gives you a competitive edge through:

Faster production rates

Lower maintenance requirements

Long-term mechanical reliability

Seamless operation with minimal human intervention